Machine tool service for cutting CNC machines

There are many reasons for our customers to make use of our machine tool service. First and foremost, of course, it is about the know-how, because the external service provider is needed where the customer himself does not get anywhere.

We therefore offer you our service as an optimal addition to your in-house maintenance.

As a manufacturer of Mattec portal milling machines and as a special machine builder, we have the necessary experience in the field of machine tools and have the perfect service equipment. Our specialist staff from the on-site service and workshop areas offer you quality advice and customer-oriented solutions.

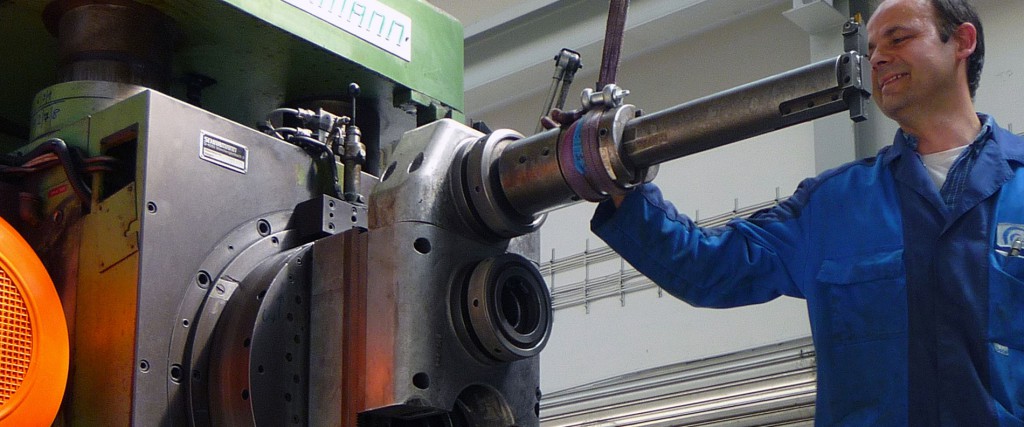

Workshop and on-site service

Depending on the type of work to be carried out, this is carried out at the customer’s site or in our factory. If it is advisable to regrind the spindle cone while it is installed on site, a machine overhaul in our company makes more sense.

Here, too, our customers benefit from our equipment as machine builders. Both minor repairs and extensive overhauls of large machines are carried out in-house. Components weighing up to 50 t are easy for us to handle. Our machine park enables necessary milling work on components up to a size of 4.5 x 4.5 x 15 m.

Our range of services in the field of machine tool service revolves around the topic of cutting CNC machines with a focus on milling machines:

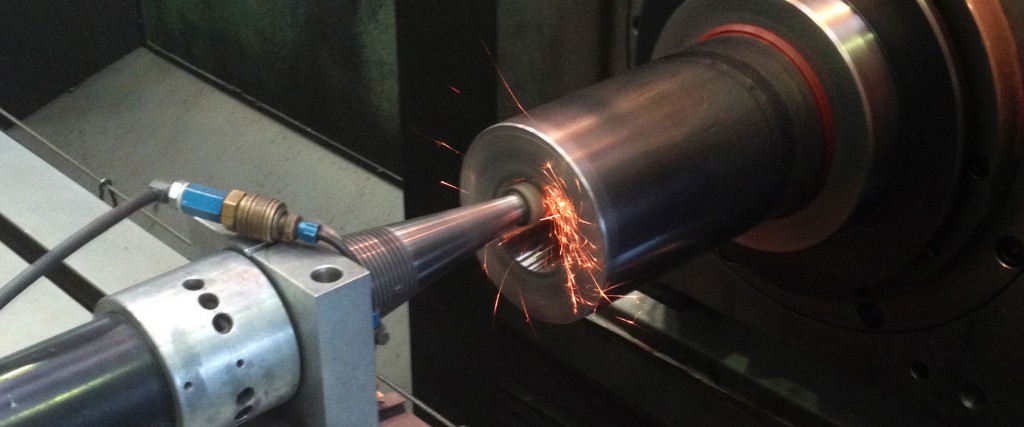

Spindle cone grinding

Damage or wear to the tool holder can be felt in many ways.

Since dismantling and reinstalling the drilling and milling spindle means an enormous amount of time and money, we have been offering regrinding of the tool holder in the installed state in the area of partial and general overhauls on machine tools since 1998.

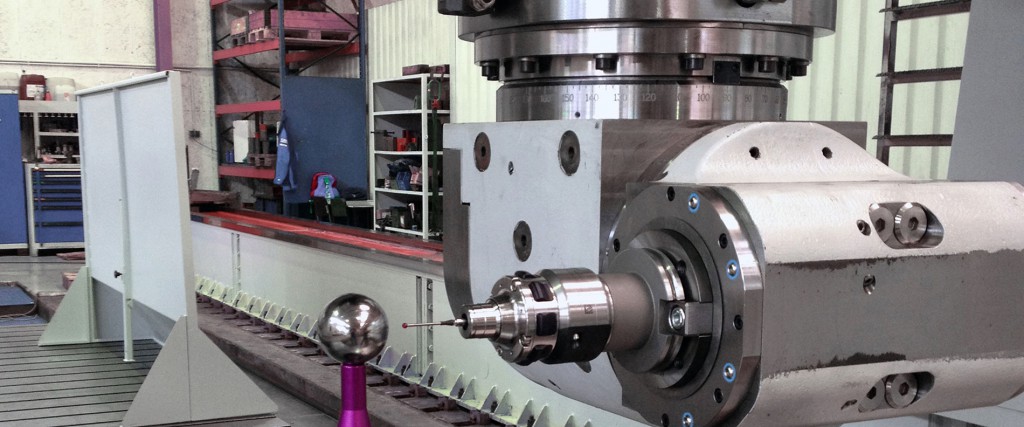

Accuracy checks

If the required working accuracy of a machine tool is no longer achieved due to geometric inaccuracies, extensive accuracy tests offer precise error localization.

We check the accuracy and behavior of machine tools, coordinate measuring machines and other positioning devices through measurements using Quick-Check or laser interferometers.

The error can then usually be eliminated by means of compensation or a message from the machine.

Partial and general overhauls

In order to prevent downtimes due to wear, specific partial overhauls of individual components or a general overhaul of the machine tool are recommended.

The most common application here is grinding the spindle cone, which we carry out on site when it is installed.

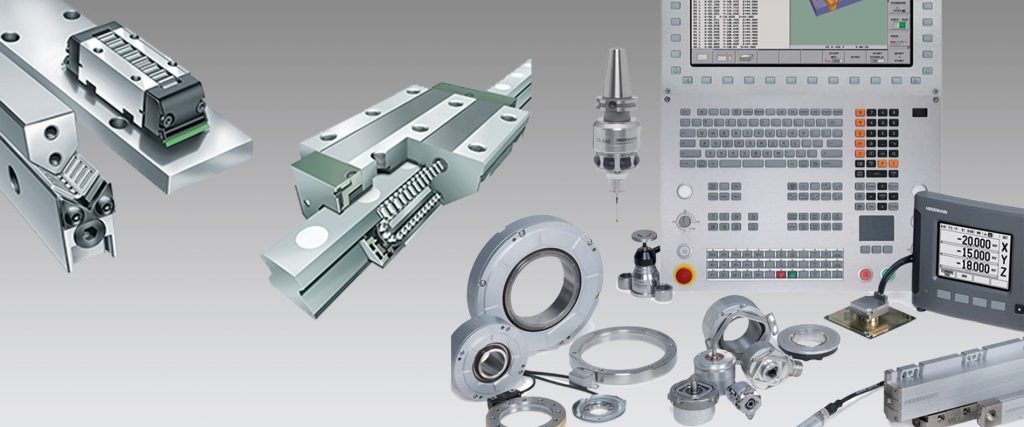

Retrofitting and expansion

Modernization measures (retrofits) are often an economical alternative to purchasing a new machine tool.

Renewing the control and drive equipment with a general overhaul of the mechanics and the integration of new technologies make an old machine competitive again.

Portfolio

Our portfolio shows you an exemplary selection of completed projects in the field of machine tool service.

Overhauls and modernizations as an alternative to new purchases clearly dominate here and are a topical issue to this day.