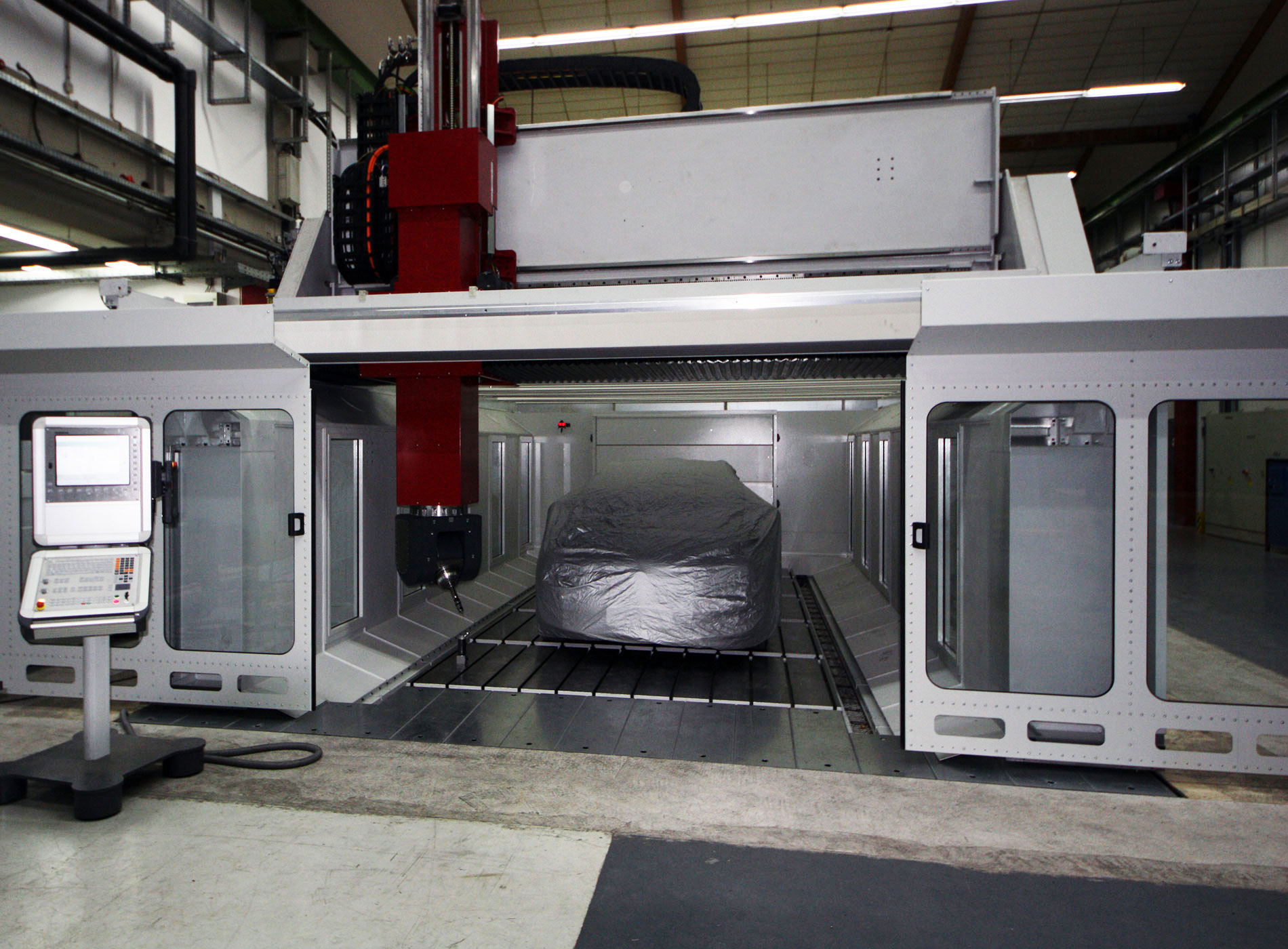

High gantry milling machine type Mattec 65-35-40 high

Customer industry:

Engineering service provider of the automotive industry

Existing process:

Milling on a moving column milling machine with circular table

Problem definition:

In the course of developing new prototypes, a machine for the 5-sided complete machining of the clay models for the model construction of whole car bodies is required. In addition, contract manufacturing jobs in the field of mould construction are planned. For these operations, the customer requires a customized machine.

SIRtec solution:

Construction of a Mattec high portal milling machine according to customer requirements, particularly designed for 5-axis machining with accelarations of up to 3 m/sek.².

Customer benefit:

The customer is able to perform the production of the clay models and contract manufacturing jobs in the field of mould construction efficiently. Due to the 5-sided complete machining, setup and nonproductive times are reduced. Furthermore, the customer can run complex milling operations without any manual intervention.

Technical specifications of the high gantry milling machine type Mattec 65-35-40 high

Travel ranges

X = 6.500 mm

Y = 3.500 mm

Z = 2.100 mm

Mounting surface

6.000 x 2.900 mm

Main spindle

automatic fork-type swivel head 90/90°

swivel level A-axis +/- 105°

swivel level C-axis +/- 200°

positioning accuracy +/- 2″

pivoting demands 0,001°

speed 24.000 rpm

tool holder HSK 63

Tool changer

Pick-Up station, magazine capacity 40 tools

Control

Heidenhain iTNC 530